If you're not using adhesive-bonded fasteners, you're losing time, money, and your competitive edge.

Adhesive-bonded fasteners have been used for decades on thousands of aircraft worldwide, including commercial and military jets. They are ideal for composite materials, as they preserve structural integrity in two ways: First, adhesive bonding means no drilled installation holes, which could compromise the composite material. Second, the adhesive itself provides a barrier between metals and composite materials, offering superior protection against galvanic corrosion. Click Bond products are designed to extend product life, reduce labor costs, facilitate more simplified repairs, and streamline the manufacturing process.

Click Bond is the leading designer and manufacturer of lightweight mounting and fastening solutions for aerospace, military, industrial, surface vehicle, and space exploration applications. Browse our entire line of adhesive-bonded fasteners by clicking here.

Watch our Unique Adhesive-Bonded Assembly Technology

Click Bond's ACRES® sleeves minimize instances of AOG by instantly repairing oversized hole conditions.

Click Bond has a complete line of BOLTMOD® and PANDOR® sleeves. Sleeves that repair structural corrosion damage, oversized or misdrilled holes. Sleeves that can be installed quickly and easily. We even offer a sleeve Trimmer Kit, which trims BOLTMOD sleeves to create 1st and 2nd oversized 06 and 08 bolts in minutes.

Download our Sleeve Solutions brochure.

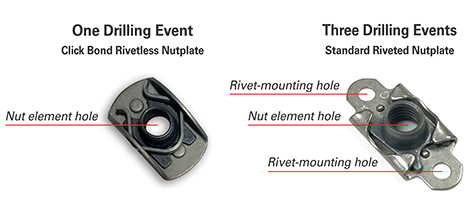

Nutplates that Eliminate the Need for Rivet Holes

Thousands of Click Bond rivetless nutplates are currently used on both commercial and military aircraft. Adhesive-bonded nutplates don’t require the two rivet-mounting holes needed by riveted nutplates, reducing nutplate installation time by 68%. They provide a high-strength bonded attachment to a variety of materials. Our split-beam nutplates provide approximately 250 reuse cycles, while reducing galling and thread seizing. FLEXBOND® sleeve nutplates provide secondary mechanical retention in addition to the adhesive and lightning strike protection. Learn More.

Swivel Cable-Tie Mounts

Composite-base, swivel cable-tie mounts with nylon or PEEK saddles offer user-designed placement schemes for routing at any angle with the added benefit of aluminum or lightweight composite bases.

Studs and Standoffs

Bonded studs and standoffs create attachment points where drill-through holes or hotwork is not applicable, all while preserving the structural integrity of the substrate.

Adhesive-bonding is ideal for attaching to highly stressed, fatigue critical, pressurized, or fluid boundary structures. That's because there are no installation holes to penetrate the surface.

Visit Our Booth # 4533 at MRO Americas & Connect with Us on Social Media